SPRL’s physical footprint consists of 9,830 square feet located in the Climate and Space Research Building (CSRB). SPRL specialized high-reliability hardware fabrication capacities include:

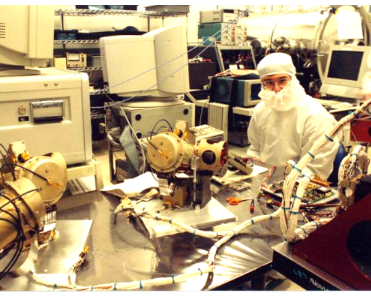

- Clean Room Fabrication—class 10,000 clean room space for the fabrication of contamination sensitive hardware, which is critical for spaceflight applications;

- Access Controlled Fabrication—federal regulations (e.g., International Traffic in Arms Regulations) require secured space for controlled technical information and the assembly of certain types of systems;

- Vibration Testing—two vibration tables, used to test flight and field hardware, are housed in a facility with specialized power and heating venting;

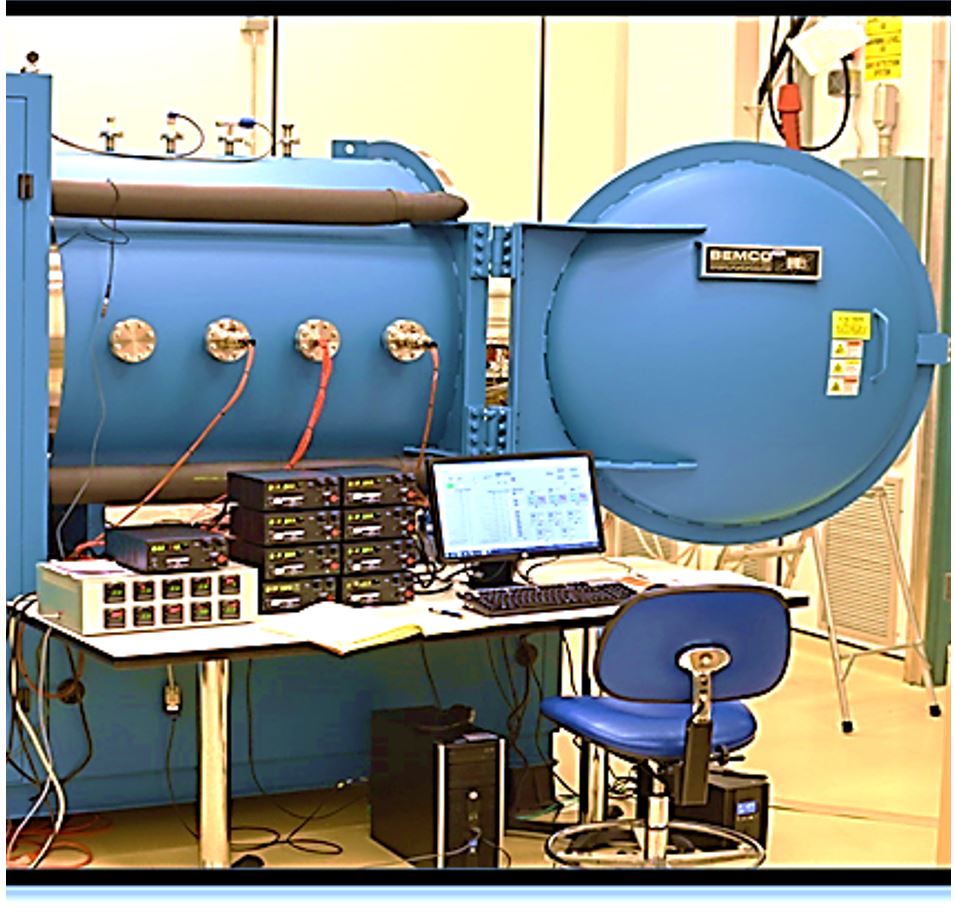

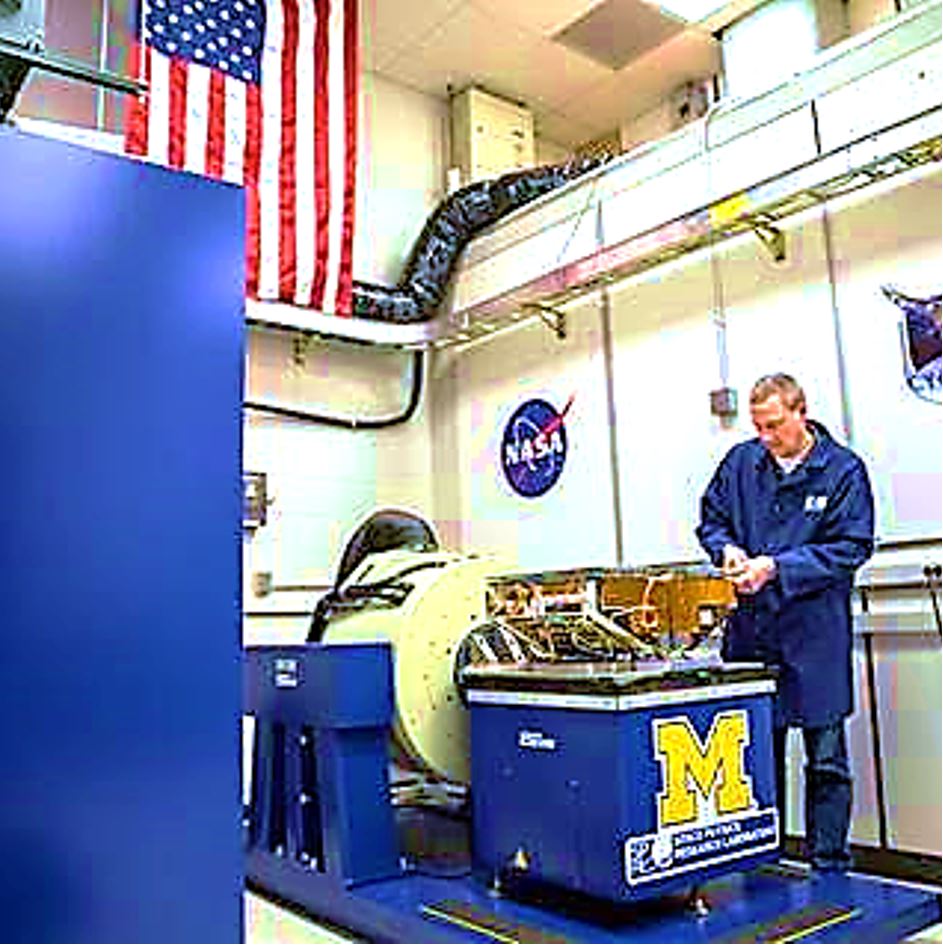

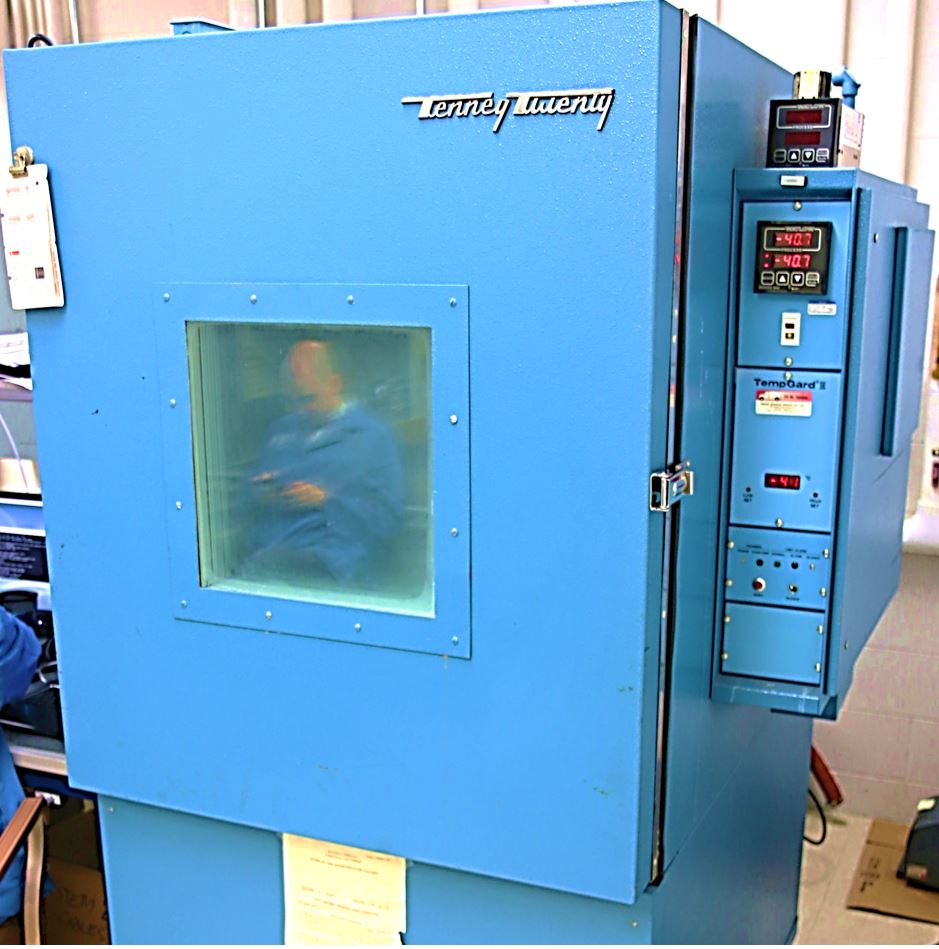

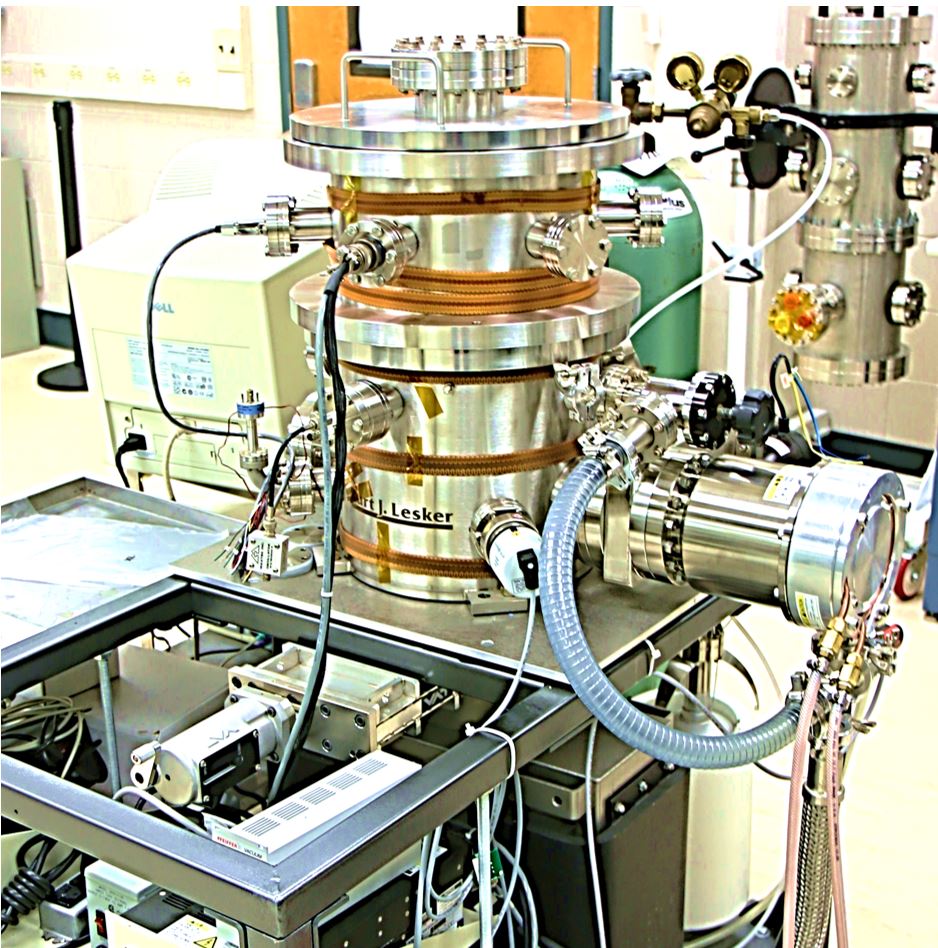

- Thermal-Vacuum Testing—two thermal-vacuum chambers, used for flight and field hardware tests, are housed in a high-bay clean room (class 10,000) facility that can be used for the integration of large systems and is supplied with liquid nitrogen handling systems, vacuum pumps, pump venting and cooling, and oxygen monitoring equipment;

- Electromagnetic Interference (EMI), Electromagnetic Compatibility (EMC) Testing—EMI/EMC testing is critical for space systems and this is done in a copper shielded room with sensitive testing gear on the third floor of SRB;

- Office Space—experienced staff of engineers and fabricators are critical to the SPRL mission and office space is second in total space allocations to fabrication (open laboratory, clean room, ITAR fabrication). In addition to special testing facilities and the associated equipment noted above, SPRL also has specialized equipment, software and associated training for PCB manufacture, magnetics, soldering, crimping, surface mount technology (pick and place machine, reflow oven), workmanship inspection, materials, parts and process control (e.g., bonded stores, parts selection and screening), contamination control, document control and security, thermal and mechanical engineering, electrical design, and field programmable gate array (FPGA) design.

Thermal and Pressure Testing

Make sure your tech works under any range of thermal and pressure conditions. Specifically, testing components for space applications requires a unique set of capabilities. Thermal vacuum testing is an important aspect of qualification testing for a wide variety of space flight components and mission-critical equipment. Thermal vacuum testing allows for the simulation of space and upper atmosphere conditions including temperature and altitude.

See our thermal vacuum facility capabilities.

Launch Simulation Testing

We’re experienced in creating high-performing vibration and shock tests for rocket launches and space environments. Our 70-plus-year legacy of space flight and launch simulation technologies makes us capable of meeting any demands of government and private sector projects. We’ll put our expertise to the task of ensuring your equipment is fit for launch.

Read more about our environmental testing facilities or view some of our most recent space missions.

High Voltage Electronics and Circuit Potting

SPRL specializes in high voltage electronics– crafted with precision and built to perform in extreme conditions. Paired with our expertise, our kiln boxes and clean assembly areas enable clean potting and encapsulation to keep the critical components of your equipment in pristine condition. From the research and development of applied HV power supply technology to custom programmable circuit devices and sensor design, we’ve got you covered.

See our electronics facilities, or read more about HV power supplies we’ve supplied for multiple space missions.

Vacuum Bakeout for Spaceflight and Testing

Our bakeout facilities are another step in the process of ensuring mission success and survivability for space-bound technology. Our thermal vacuum bakeout prevents the contamination of sensitive hardware, reducing outgassing to an acceptable level for flight equipment associated with instrumentation that is sensitive to molecular contamination. If you’re sending technology to space, we are a one-stop-shop for the design, fabrication, testing, and preparation of that equipment.

See some of our recent projects that have gone to space

Other Capabilities

XTRM-SPRL is such an end-to-end operation that it’s difficult to fit all our abilities under one category. Other services we offer include:

- Systems engineering and program management expertise in complex integrated systems operating in harsh environments

- Expertise in RF engineering, thermal engineering, motor and servo control and flight software

- Drafting and mechanical design, computer graphics and instrument/machine shop facilities

- Surface-mount technology equipment

- Screen room for EMI/EMC testing

- Spaceflight operations center